Rectangular cheese mold

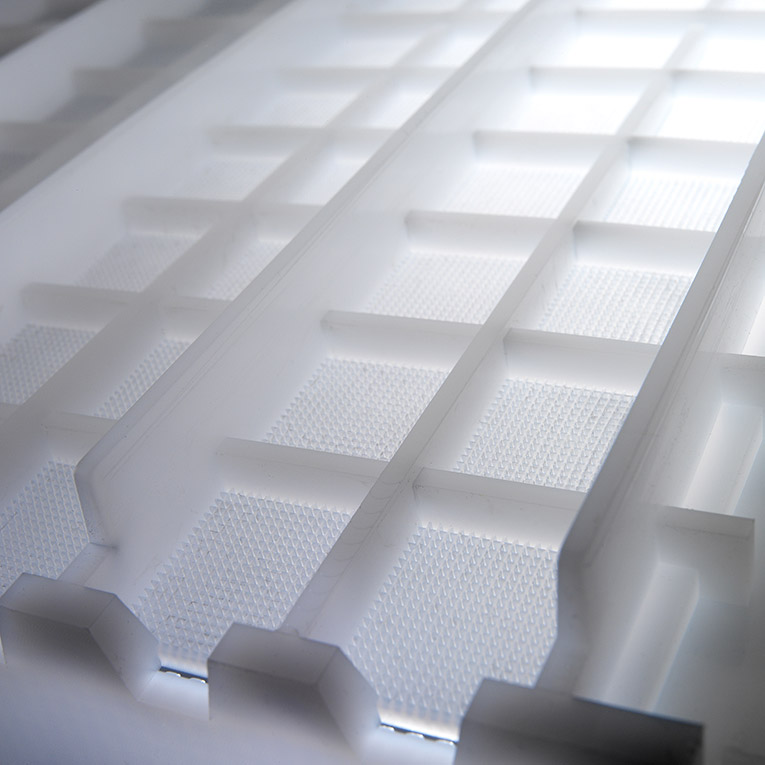

Interchangeable inserts in the same tool

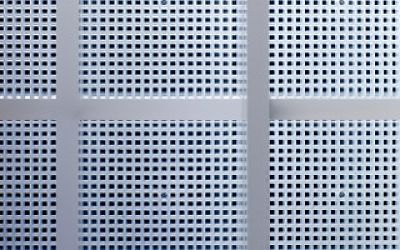

(Number!) Holes for maximized aging opportunities

Starting point

Cheese mold for the fully automatic processing of raw materials in a modular system for different process processing

Challenge

The need for ventilation of the comparatively large mass of the raw material via various slides in the injection mold insert change system, depending on the production process

Solution

Mapping of the (number!) Tire holes in the injection molding process without further processing - insert change system in the same tool for cost savings and flexibility in production

Advantage

Considerably cost-saving compared to separate designs thanks to interchangeable inserts - finished part from the machine without any further processing steps required